6.1 Pour successively into the butyrometer:

- 10 ml sulphuric acid.

- 9 ml distilled water. (must not be mixed with the acid).

- Exactly 2.5g powder.

- 1 ml Amylalcohol.

6.2 Close the butyrometer with the caoutchouc stopper and shake untill the powder is dissolved. Turn the butyrometer upside-down 5 times.

6.3 Boil in water bath for 5 minutes at 65 ± 3o C.

6.4 Spin in the centrifuge for 5 minutes at 65 ± 3o C, (mode “Gerb”)

6.5 Shake for further 1 minutes. Turn the butyrometer upside-down 5 times. Spin in the centrifuge for 5 minutes at 65 ± 3o C, (mode “Gerb”)

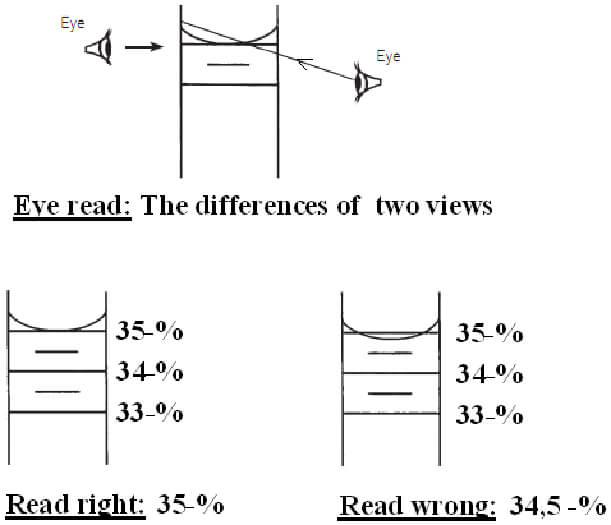

6.6 Read result:

Adjust the fat colum by using the stopper, so that it will be in the graduated part of the butyrometer.